Description

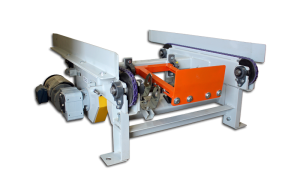

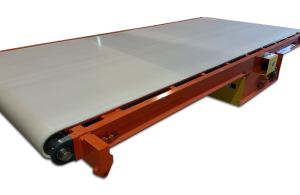

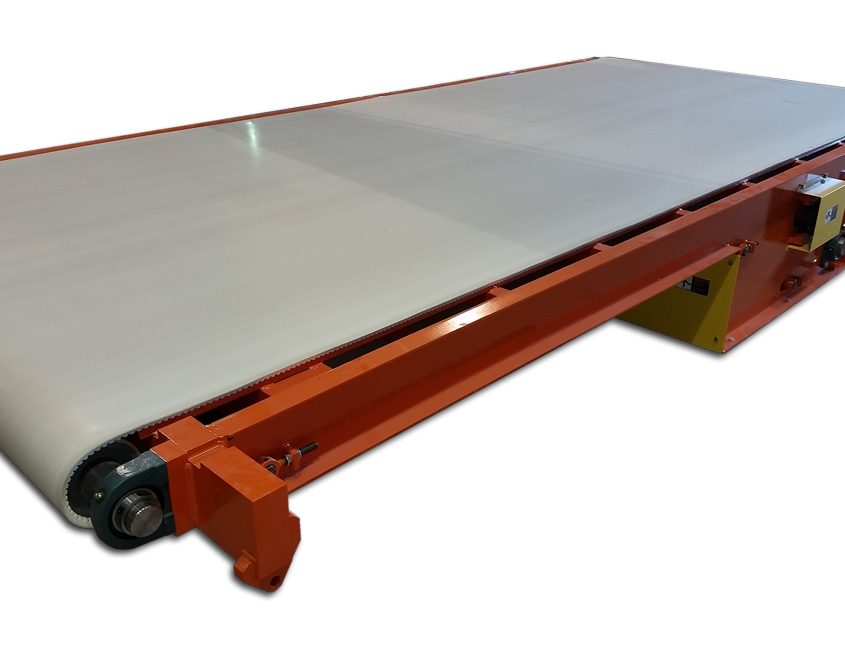

Belt conveyors have a belt running over a slider bed surface or a bed of rollers. Fabric belts are friction driven using a lagged drive pulley. Plastic and wire mesh belts are direct driven using drive shafts and sprockets. Flat, V-trough and adjustable beds are common requirements requested.

Belt conveyors are needed when conveying loose or small parts or when products do not have a flat bottom surface to convey. The belt helps to support the irregular shapes allowing them to be successfully transported down the conveyor.

Applications

Automotive – Tire, Seat, Powertrain

- Belt conveyors typically use a flat belt with a friction drive pulley and a take up pulley

- Belt conveyors with fabric belts can range from 6” wide up to 117” wide (3 meters) based on belt availability

- Standard belt speeds range from 10 to 200 fpm

- Special component options will allow belts to run as high as 400 fpm

- Fixed end pulleys help product transitions

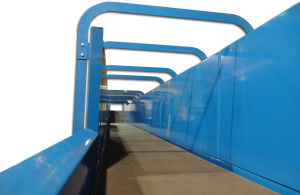

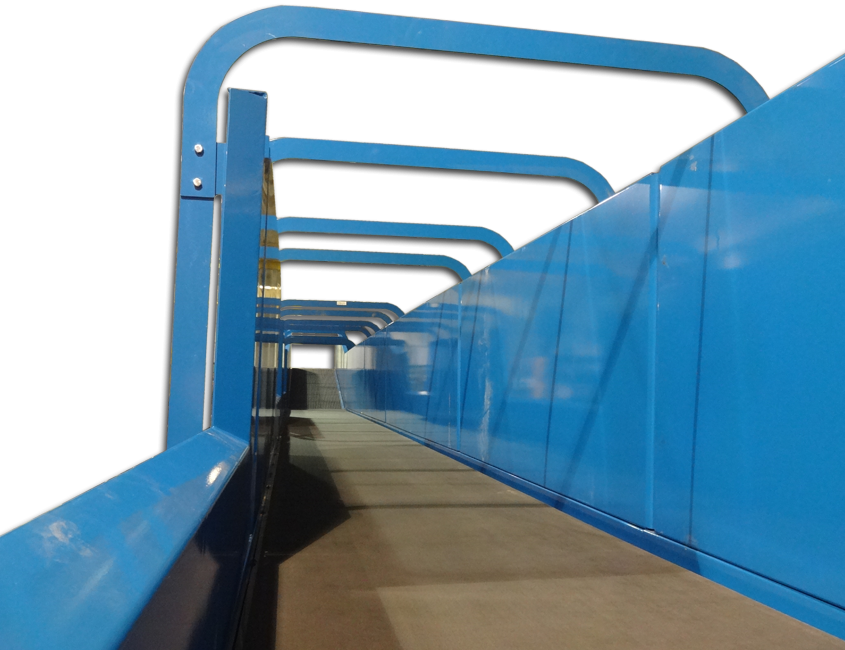

Paper, Textile, Foam and Pipe Handling

- V-trough or profile beds assist in conveying round products like rolls of paper, cloth, foam and pipes

- With inner frame tilting capabilities, unloading to a perpendicular conveyor is easily managed

- Standard belt speeds range from 10 to 200 fpm

- Conveyors can be as short as 3’ long or run for 200’ in length

Stamping and Metal Processing

- Slider pans can be adjustable to support multiple size product diameters if required

- Beds can extend or retract for ease of die change out in stamping processes or for crossing aisle ways for continuous conveying

Options

- Belt type

- Roller or slider bed

- Purchase component brands

- Drive configurations

- Control packages

Downloads

Industries