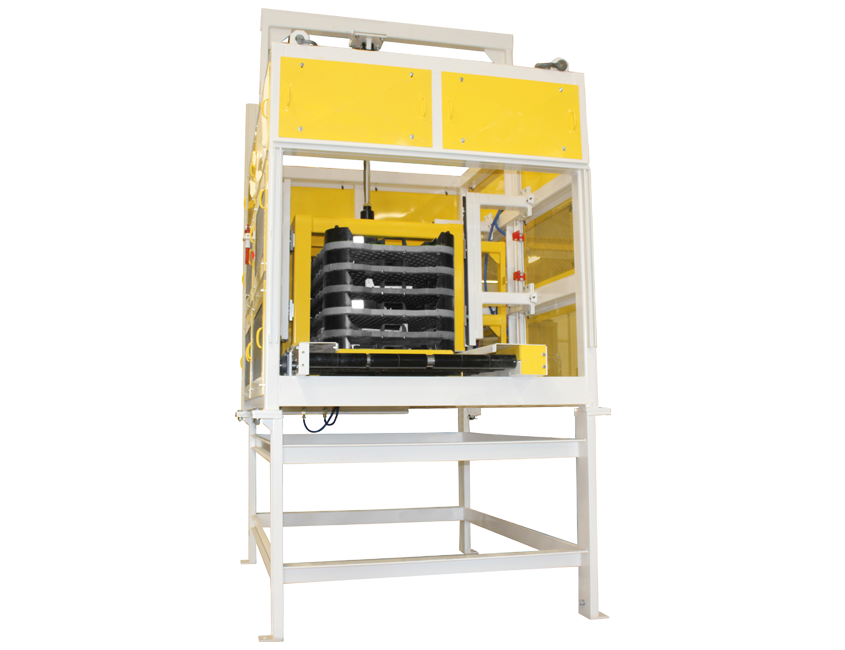

Pallet Stacker Description

Stackers are used to stack tires, racks, containers, pallets loaded with products, which come in a wide range of sizes and shapes. The Stacker consists of a magazine to hold a stack of products as they accumulate; forks or clamp to engage the stack; electric, pneumatic or hydraulic lifting actuators and an in-feed conveyor. Most products are normally conveyed into the unit and stacked from 2 to 15 high depending on structural integrity of the product. After stacking product, stacks can be unloaded via forklift or conveyed down stream.

These devices can handle a variety of racks, containers, tires and pallets. In most cases, Stackers are built to order based on the application needs. The sequence of a stacker is as follows: a product is conveyed into the magazine where forks or clamps engage and lift the product allowing the next product to enter underneath. Once positioned, the carriage lowers the stack to sit on the bottom product. After the stack is formed, the exit conveyor moves the stack down stream where it can be conveyed or removed with a forklift. The maximum throughput for this unit is approximately 5 products per minute and is product specific.

Stackers are primarily used to reduce the product footprint for storage, transportation and handling products.

Pallet De-Stacker Description

De-Stackers are used to singulate racks, containers, loaded skids and products that are stacked. A De-Stacker consists of a magazine that holds a stack of products; forks to engage the stack; electric, pneumatic or hydraulic lifting actuators and an exit conveyor.

De-Stackers have a basic function to singulate and release one product at a time via the exit conveyor. However, with the wide variety of sizes and products from racks to skids, most De-Stackers are built to order. Maximum throughput for this unit is approximately 4 products per minute and is product specific.

With De-Stackers having such a wide range of design possibilities, they can be found in most industries, including automotive for tire de-stacking, automated warehouse storage, appliance shipping docks, vehicle assembly racks and large volume parts container storage to name a few.

Applications

Automotive – Tire and Wheel

- Tires, seat pallets, racks, containers and panels

- Tires – 22” to 36” diameter, 5.25” to 14” wide and 40 to 120 lbs. each

- Pneumatic, electric or hydraulic powered motion

- Provided with basic sensors and valves

- Rates of up to 6 tires per minute

Material Processing

- Skids, racks and containers

- Product sizes – (30” to 60” wide) x (48” to 120” long) x (4” to 60” high) and 60 lbs. to 2500 lbs. each

- Pneumatic, electric or hydraulic powered motion

- Provided with basic sensors and valves

- Rates of up to 6 products per minute

Automotive – Modular Assembly

- Pallets/racks – (30” to 60” wide) x (48” to 120” long) x (4” to 60” high) and 60 lbs. to 2500 lbs. each

- Pneumatic, electric or hydraulic powered motion

- Provided with basic sensors and valves

- Rates of up to 4 products per minute

- Electrical, pneumatic or hydraulic actuated

- Maintenance pins

- Lubrication, chain oilers

- Torque limiters

- Integrated conveyors

- Purchase component brands

- Control packages

- Safety guarding and fencing