Description

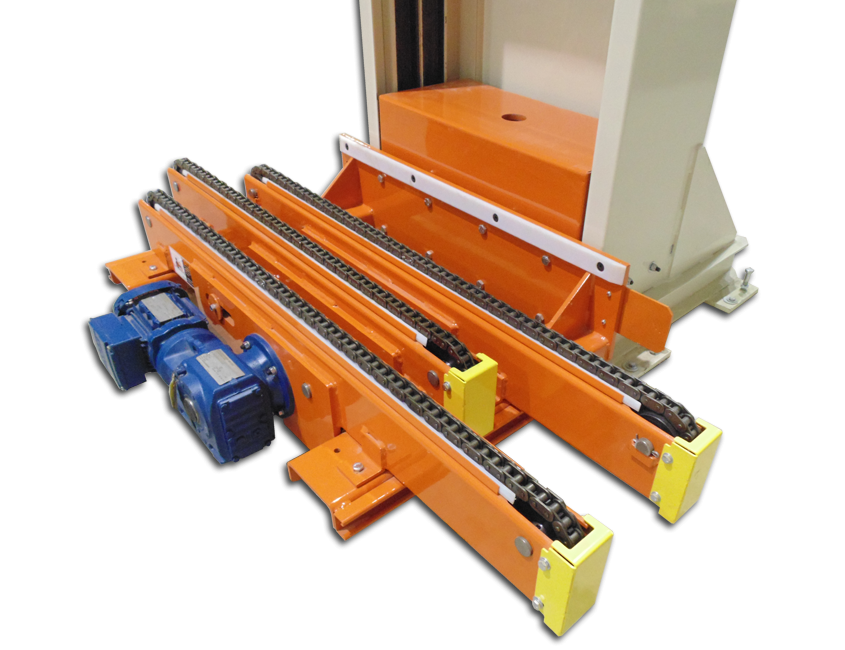

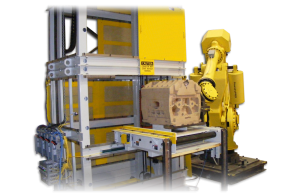

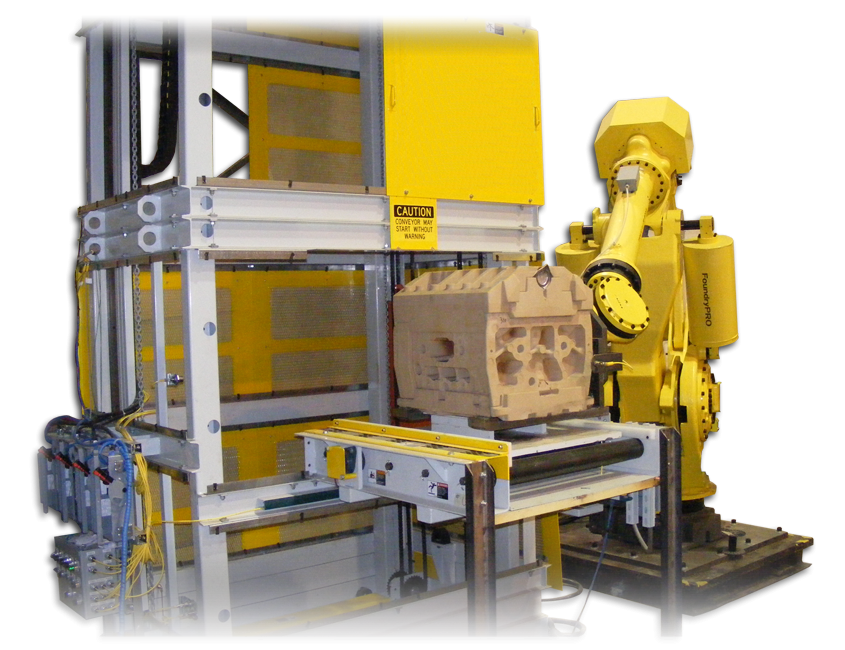

A Vertical Reciprocating Conveyor (VRC) is a conveyor mounted to a platform which is raised and lowered to multiple elevations. The platform is attached to vertical chains which are mounted within a frame structure. A drive will power the chains to move the platforms. Products ride on the conveyor, normally in one direction known as up-service or down-service.

Due to application and elevation requirements, VRCs are a build to order machine. Loads, product sizes and speed functions influence the custom design. Product flow can be Z, C, Right and Left. That means, when a product enters, it can exit at a different elevation in one of four directions. “Z” continues the direction of flow, “C” means the product exits the same way it entered, Right or Left is 90 degrees to the entry.

VRCs are used for continued service on conveyor lines when the elevation changes. Automotive assembly plants use VRCs to deliver parts from dock areas to the assembly line. VRCs are utilized in over/under work stations with closed loop pallets. Moving products to or from upper level storage areas to shipping docks and servicing multi-level trailer conveyors at the docks areas are also typical uses for VRCs.

Applications

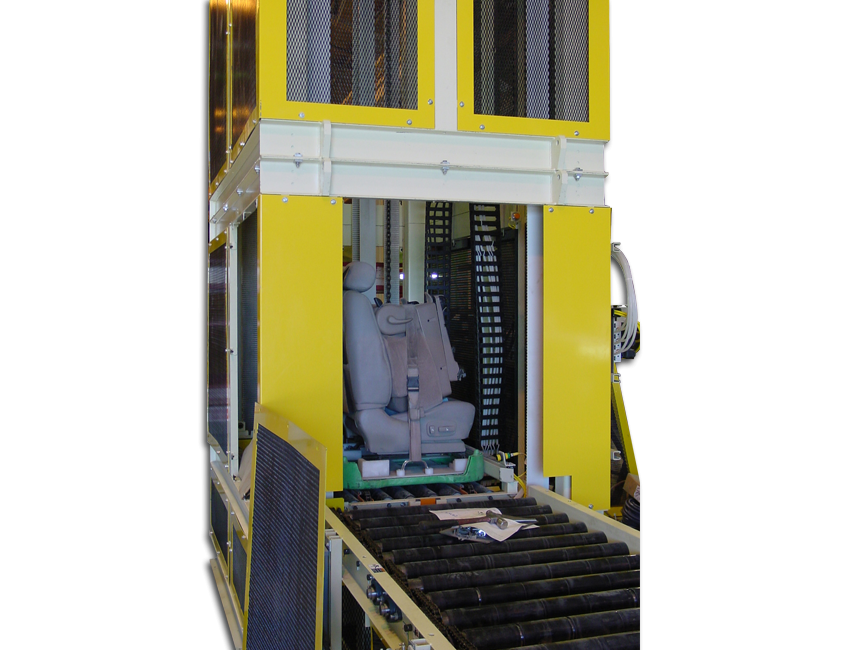

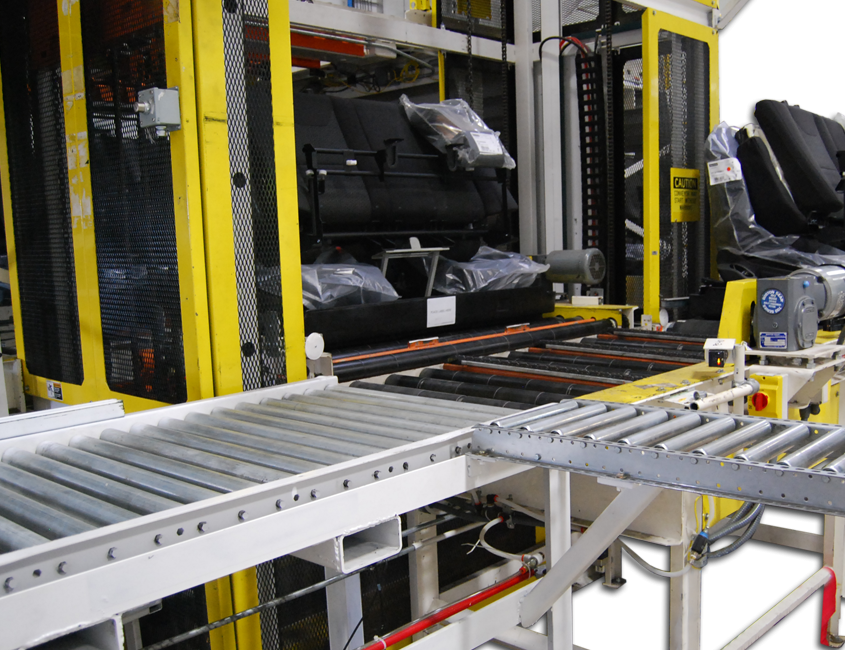

Automotive – Seat Handling & Modular Assembly

- Seat stripper lines to service upper and lower levels to mainline

- Trailer load and unload multi-level

- Main level to upper delivery

- Powertrain work station

Material Handling

- Line elevation changes

- Over/under work station

- Upper level storage

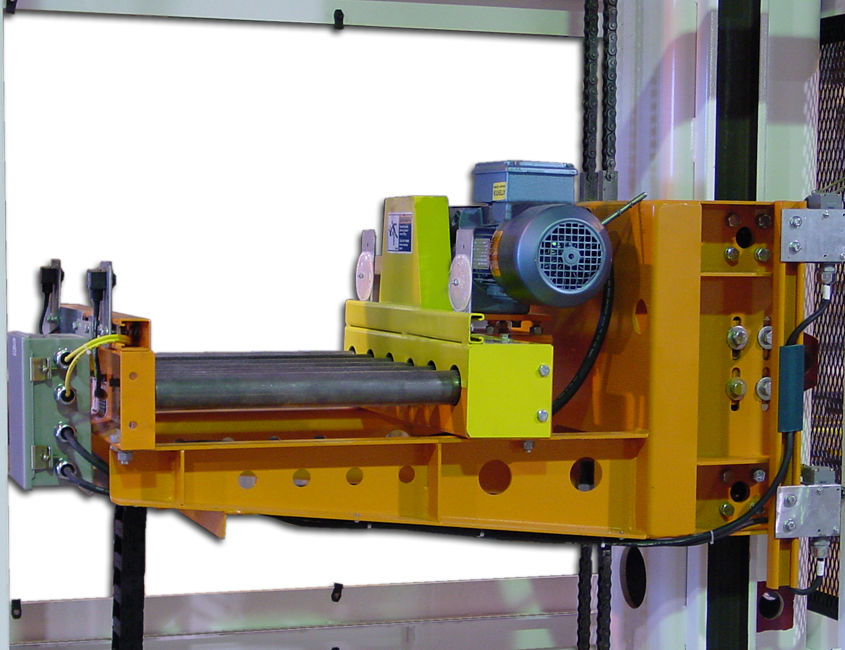

- Electrical, pneumatic or hydraulic actuated

- Conveyor options

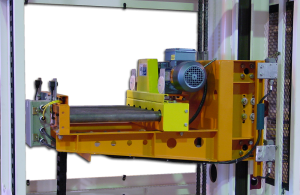

- Chain lubricator

- Purchase components

- Maintenance chains

- Anti-drop brake

- Control packages