Description

Pallet Dispensers are used to separate and dispense one pallet or slip sheet at a time. The dispenser consists of a magazine to hold a stack of empty pallets or slip sheets; forks to engage the stack; electric, pneumatic or hydraulic lifting actuators and an exit conveyor. Pallets come in a wide range of sizes and shapes. The style of most pallets are referred to as “two way” or “four way” pallets. With these pallets requiring different fork and lifting functions, there are two basic dispenser designs, a two way and a four way pallet dispenser. Most dispenser types and sizes are picked per application requirements.

Pallet Dispensers are typically designed to handle one size pallet or slip sheet. The stack is loaded in the magazine via a forklift or an in-feed conveyor. The forks engage the second pallet and lift the stack off the bottom pallet. The bottom pallet exits on an exit conveyor and the stack is lowered back onto the conveyor. The process repeats until the dispenser is empty. Slip sheets are dispensed basically the same way.

Pallet Dispensers have a high usage in palletizing processes where pallets need to be dispensed one at a time to a palletizing cell for product loading. By adding and relocating some sensors the dispenser can also be used to stack empty pallets.

Applications

FBD4: 4-Way Fork Box Pallet Dispenser

- Designed for 40” wide x 48” long 4-way pallets

- Straight, left or right pallet exit

- Standard magazine capacity of 15 pallets

- Pneumatic adjustable forks (60 PSI input)

- Integral hydraulic scissor lift

- Integral 2-strand direct drive chain conveyor

- 12” minimum top of chain height

- Minimal guarding required

- Photoeye sensors for product detection

- Ultrasonic sensor for lift positioning

- Basic or full controls packages available

- DWG files with footprint available for download – Standard 40 x 48 and Standard 48 x 40

- Watch the video to see it in action

CLD4: 4-Way Carriage Lift Pallet Dispenser

- Application specific parameters

- Designed for a large range of size 4-way pallets

- Straight, left or right pallet exit

- Standard magazine holds 12 pallets, bolt on extensions available

- Pneumatic actuation for lifting and securing pallet (80 PSI input)

- Integrated chain driven live roller or chain conveyor options

- All moving components guarded

- Photoeye sensors for pallet detection

- Basic or full controls packages available

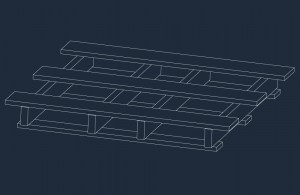

Two-Way Pallet Dispenser (Build to Order)

- Fork engagement limited by pallet style

- Pallets only have fork pockets on opposing sides and winged pallets

- Pallet sizes – (36” to 48” wide) x (36” to 48” long) x (4” to 6” high)

- Magazine holds a stack of 15 pallets

- 25 lbs. to 100 lbs. each

- Pneumatic and electrical powered motion

- Provided with basic sensors and valves

- Basic or full controls packages available

- Electrical, pneumatic or hydraulic actuated

- Fork configurations

- Integrated conveyors

- Product entry and exit

- Adjustable magazine

- Magazine extension

- Guarding or fencing

- Control packages