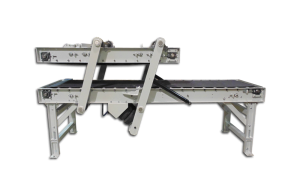

Description

Bag Flatteners are two belt conveyors inverted to each other and used to compress or flatten products. The two conveyors are attached with two linkage arms and air bags. The upper conveyor weight is used in the flattening process. Trackmate belts are typically used, however, other belts are available based on application needs.

The bottom conveyor which is longer than the upper conveyor, typically is mounted on legs mating up to an in-feed and an exit conveyor. The upper conveyor, mounted on the linkage arms is adjusted to the desired flattening height. With both conveyors running, the irregular package enters the flattener and exits compressed or flattened to the required height.

These conveyors are primarily found in the palletizing process where bags need to be flattened for controlled layering on pallets prior to stretch wrapping. Bag Flattener conveyors have also found their way into the insulation and felt industries where controlled flattening is required.

Applications

Standard Specifications

- 120″ long lower belt conveyor

- 72″ long upper belt conveyor

- 24” wide black Trackmate 120 EMB Belt

- Leg supports for 22″ minimum top of belt (+/-2″ adjustment)

- Welded construction

- Adjustable air bag actuated opening from 3″ to 12″

- Product weight up to 80 lbs.

- Available as Horizontal and Incline

- Build to order specials

Palletizing

- Bagged products – 5 to 50 lb. bags of flour, sugar, dog food, lawn and garden and building products

- Flat products – insulations to felts

- 24” to 36” belt width

- 10’ to 15’ long

- 20 to 100 feet per minute

- Throughputs up to 12 bags per minute

- Pneumatic compression

- Manual pneumatic valve

- Electric driven conveyors

- Conveyor length

- Conveyor height

- Belt width

- Horizontal or incline

- Operating voltage

- Drive brand

- Basic or full controls