Description

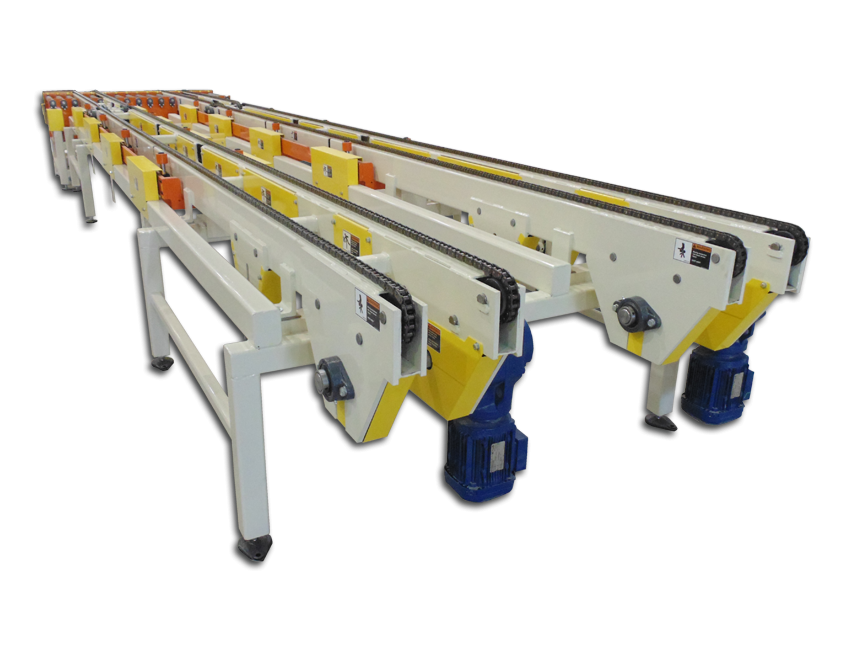

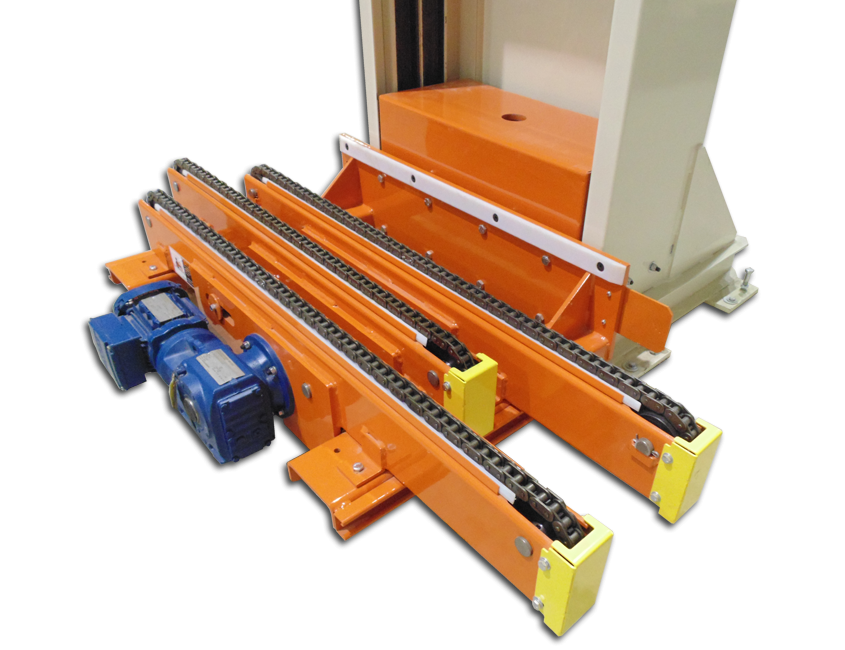

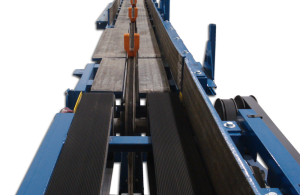

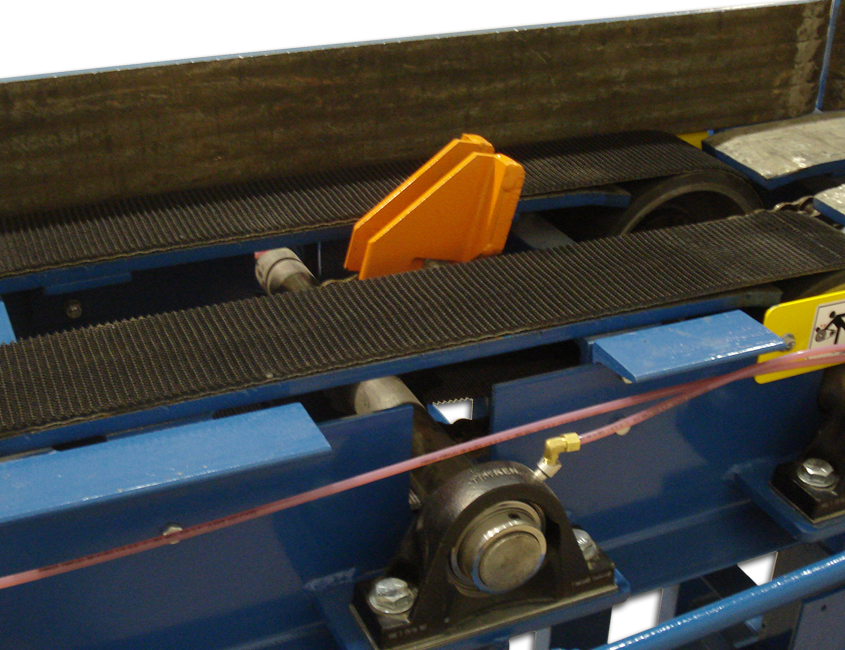

Chain Conveyors use chains running on tracks to convey products setting directly on the chains. They consist of a frame and track, a drive sprocket, a take-up sprocket, a drive and the chain. These conveyors can range from single strand to multi-strand (2 to 8 strands). The most common chain conveyor is a 2 strand chain conveyor moving pallets.

Chain conveyors are an efficient, reliable and cost effective way to move products. As a build to order product, chain conveyors can be configured to handle most large, heavy or long products. Special attachments may be added per application allowing for part separation and indexing. With vertical motion (air bags or cylinders) added to a chain conveyor, the conveyor then becomes a pop-up transfer. These conveyor can be integrated with a number of other components like chain driven live roller conveyors, pallet dispensers and stackers.

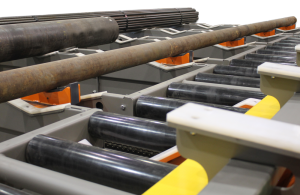

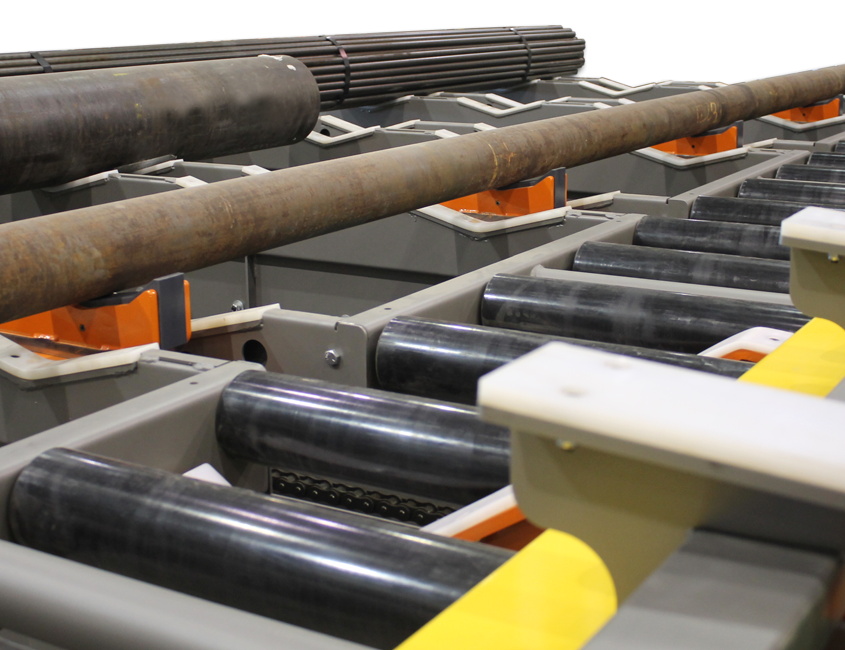

Tow line conveyors are typically a single strand chain conveyor with attachments (dogs) to move carts along assembly lines. Multi-strand chains have many uses from moving palletized loads to carrier boards on assembly lines to conveying long products like pipes, tubing, rolled products or lumber. Moving 50’ long products to saw lines is an ideal application for a multi-strand chain conveyor.

Applications

Automotive

- Bringing parts to the assembly line cost effectively

- Moving engines and transmissions for testing and assembly for powertrain lines

- Conveying full or empty racks efficiently around the plant

- Conveys seats nested in a seat pallet on its way to storage or the vehicle

- Container of parts to modular assembly

Material Processing – Pipe Handling

- Shingle pusher conveyors

- Single strand tow line conveyors connect to wheeled carts to convey to the next process

- Shuttle conveyors lift and transfer products to process lines like saws and shears

- Appliances on carrier boards at assembly lines

- Over under work stations

- Purchase components

- Guides

- Tread plates

- Controls