Description

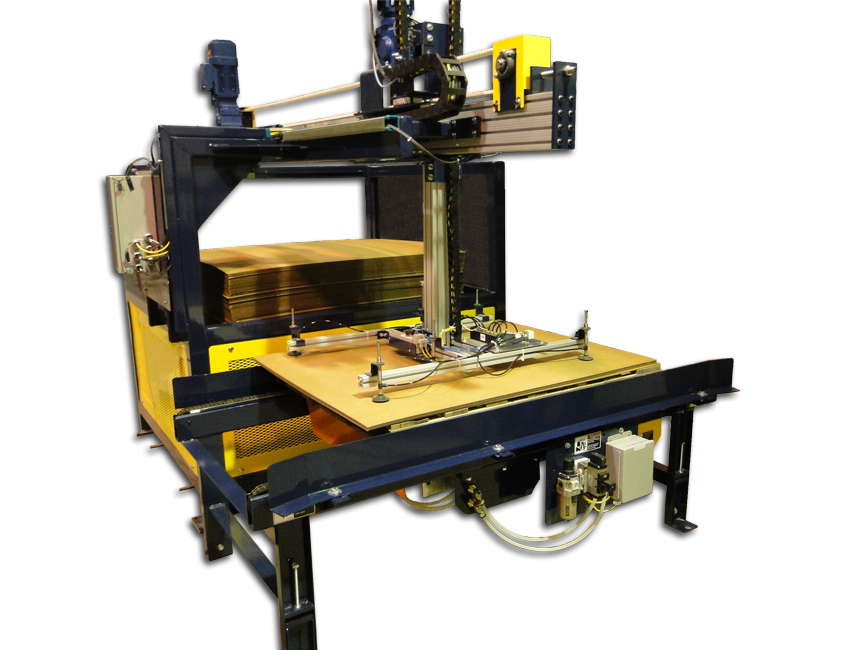

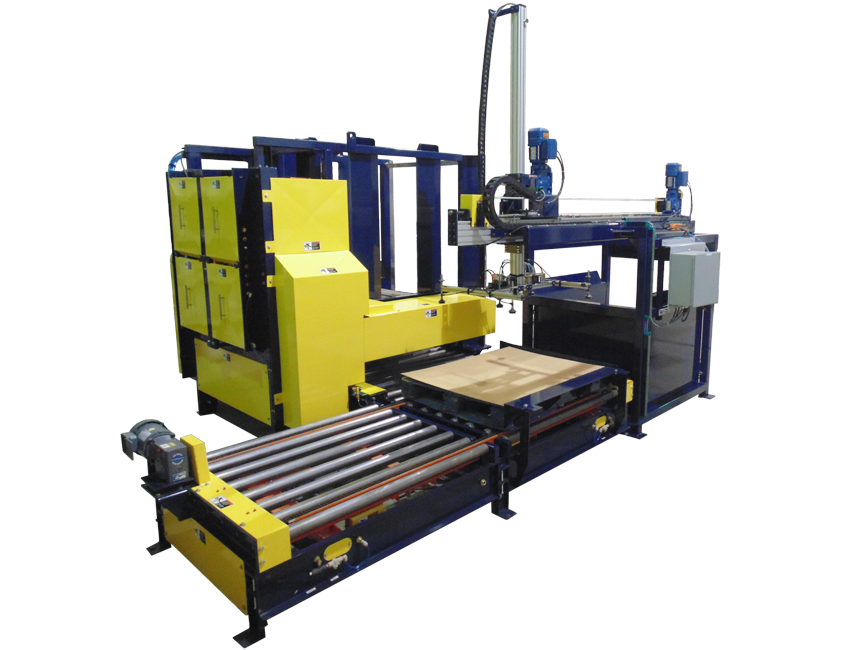

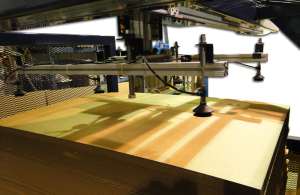

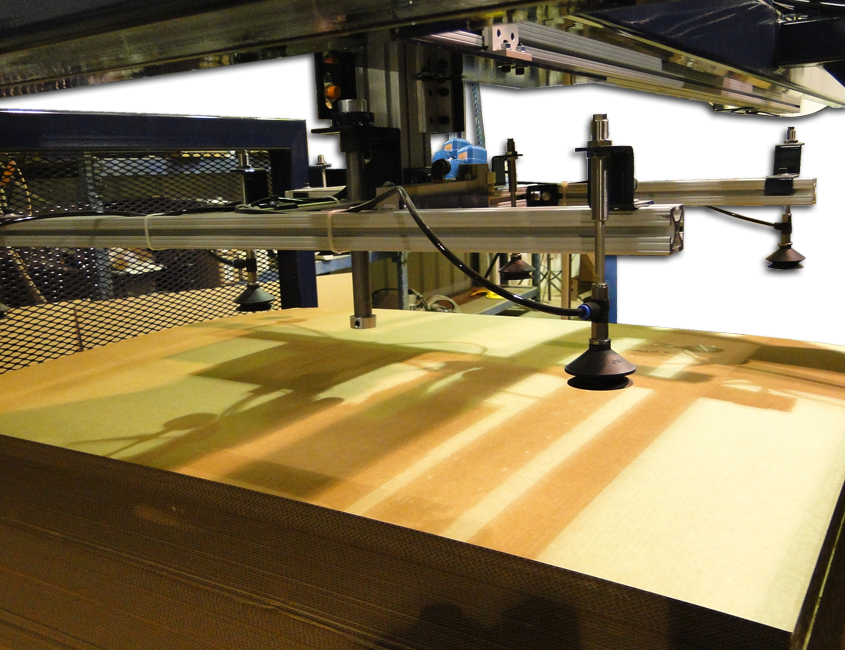

The Pick & Place is a piece of equipment consisting of a storage magazine, a belt driven carriage transfer with a bed of vacuum suction cups with vertical and horizontal motion. Sensors are used for motion control and to detect stack height in the magazine.

The Pick & Place lines up with in-feeding and exit conveyors to supply slip sheets to the pallet being conveyed. The carriage with vacuum suction cups are lowered to detect and pick up one slip sheet at a time off of a stack stored in the magazine. The carriage moves up and then horizontal to place the slip sheet directly over a pallet prior to palletizing or between each layer of products when layer forming.

Palletizing lines and product layer forming are the most common places utilizing pick and place devices. Corrugated shipping base boards, short sided pallet tops and bottoms also can be dispensed using a pick and place.

Companies are using pick and places today to stack or dispense plywood and polymer carrier boards (base board) for assembly lines.

Applications

Automotive – Modular Assembly

- Media placement between layers for protection

- Carrier boards under product assembly

- Base plywood to build product on

Palletizing

- Used in line with pallet dispensers

- Locates slip sheet centered on pallet

- Layer forming for bottling

- Vacuum system and cups

- Magazine option

- Service conveyor

- Lift capacity

- Cycle speed (thru put)

- Controls