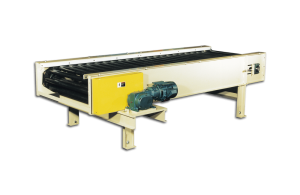

Description

Roller Flight Conveyors typically use parallel strands of chain located on the outside edges of the conveyor. Gravity roller axles are then attached to the chain. These rollers can rotate under the product, permitting the products to accumulate over long distances. This type of conveyor design is very rugged and can deliver many years of service with minimal maintenance. Built as a welded conveyor with CC5 chains and 2 1/2”or 2 9/16” rollers, this is a durable solution for up to 200’ of conveying.

Roller Flight Conveyors are for minimum pressure accumulation, products touch each other as they accumulate on the conveyor. These conveyors are often installed in unused ceiling spaces. Runs as long as 200’ to 300’ in length can be powered with one drive depending on product weight and speeds.

You can find these conveyors throughout the automotive industry for delivering seats, tires and cockpits to the assembly line. These conveyors can also be found at assembly or accumulation lines when products are set on build pallets or slip sheets.

Applications

Automotive – Tire and Wheel

- Main chain – two strands of CC5, 6” pitch punched mid-pitch for 11/16” hex axle

- 2 1/2” or 2 9/16” OD rollers with grease packed bearings, 11/16” hex axles pin retained

- Side low mounted head end drive with overload protection

- Hold downs

- Flow rail

- Legs/ceiling hangers

- Roller type

- Roller coating

- Chain type

- Hold downs

- Flow rail

- Purchase components

- Controls