Description

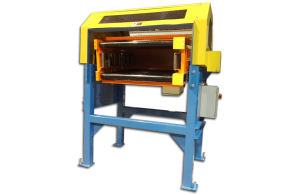

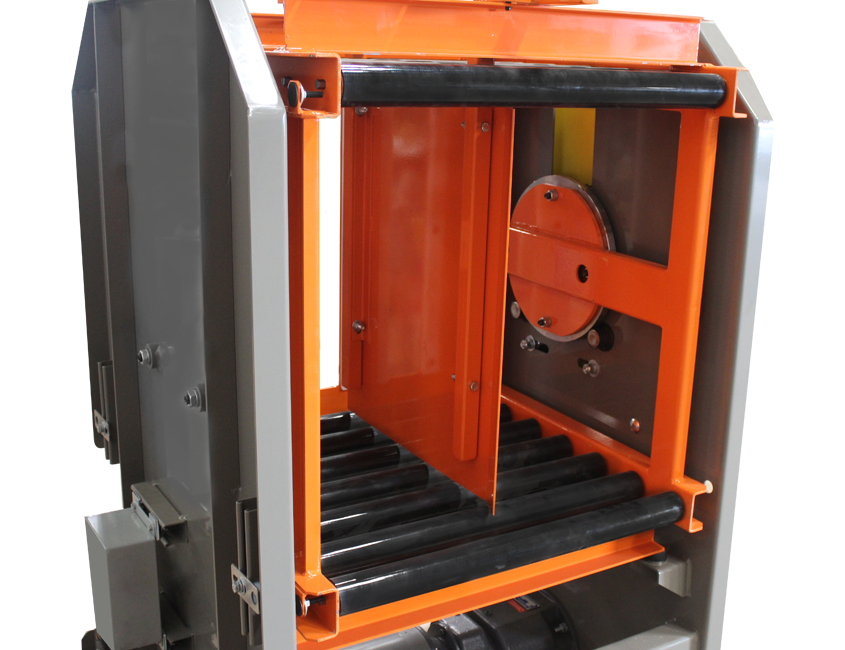

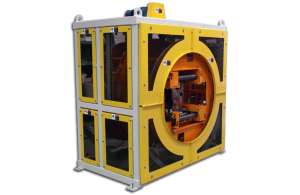

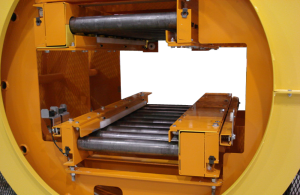

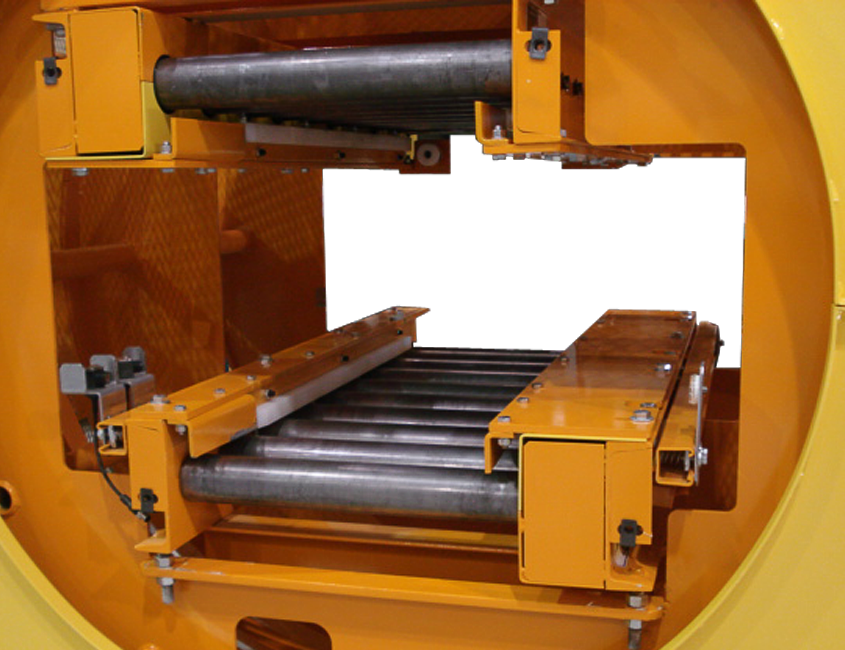

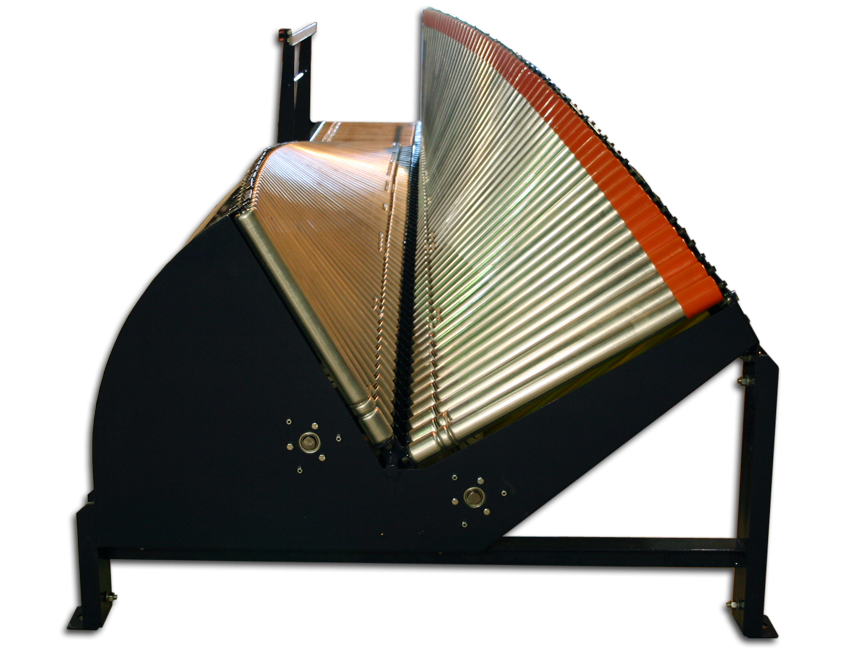

A Turnover is a device that repositions a product from bottom surface down to bottom surface rotated 90 or 180 degrees. There are many designs to choose from. A common turnover has an outer frame with an internal carriage holding two conveyors inverted to each other. This style can be designed to rotate or flip the product. A helix conveyor can also be used to rotate products 90 degrees at a time.

With a carriage style turnover, products enter the carriage from an in-feed conveyor. The upper conveyor clamps down on the product and the entire carriage rotates 180 degrees. The clamp is released and the product conveys out. The helix conveyor receives the product and rotates it through a series of rollers on an incremental pattern allowing for the product to rotate 90 degrees at a time.

Tire turnovers change tires from curbside up to curbside down. Engine blocks are turned over for machining process. Boxes needing to be labeled on multiple sides are rotated. Carpet tiles being turned over for applying adhesives and product inspection lines are common places for turnover devices.

Applications

Automotive

- Engine block and head turnovers in the machining process

- Tire turnovers position the tire for the worker to install on vehicles, weight apply stations and tire mounting

- Turning over brake rotors for machining

Industrial

- Door turnover (above)

- Washer applications

- Foundry environments

- Heavy and light duty assembly

- Inspection stations

- Print and apply

- Electrical, pneumatic or hydraulic actuated

- Conveyor options

- Purchase component brands

- Controls packages