Description

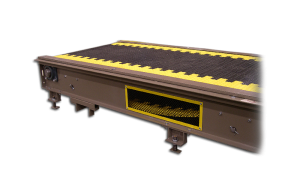

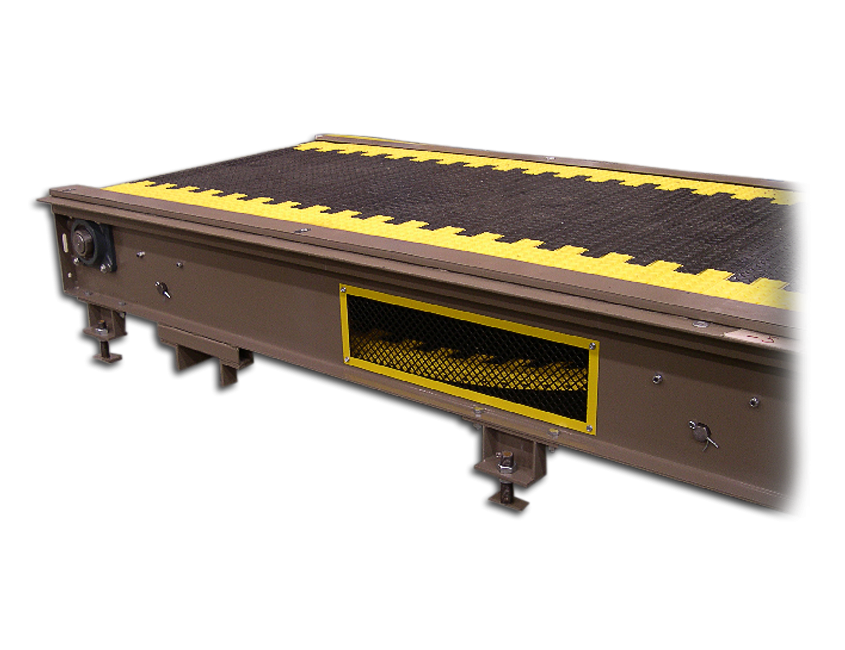

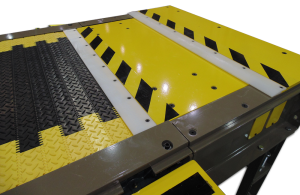

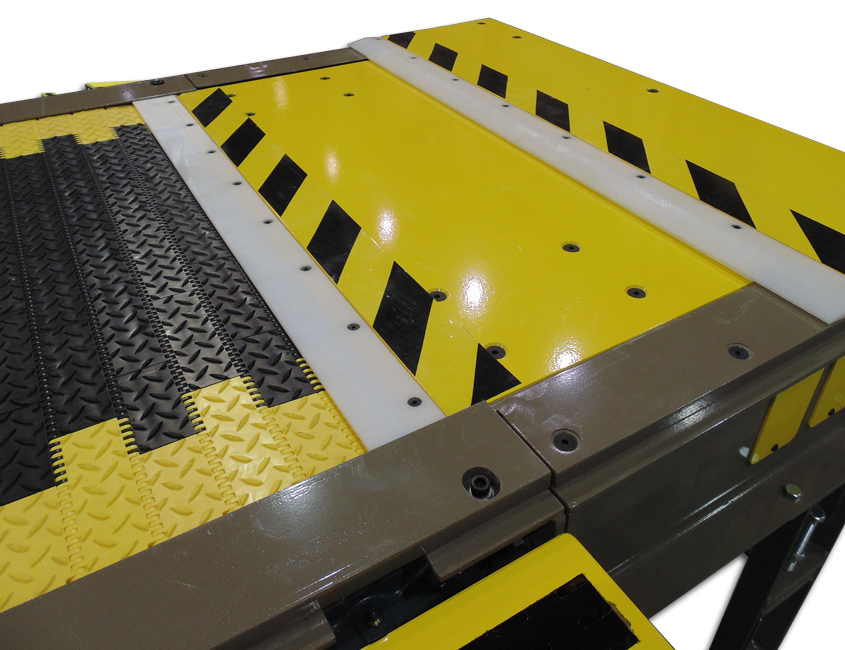

The Ergo Conveyor is a metal framed conveyor with a powder coat finish utilizing a modular plastic belt with a nonslip surface. Two drives: a main drive and a tensioning drive are used to tension the belt providing a stable, non surging motion as workers step on and off the belt. HTC has provided conveyors in widths from 30” to 120” wide and lengths ranging from at 20’ to 210’ long.

The Ergo Conveyor was designed to remove the need for workers to walk along when assembling parts on vehicles. With this type of conveyor, the worker steps onto the moving belt, performs their job while riding along at the same speed as the vehicle they are working on. Once completed, they step off the conveyor, return upstream to the beginning of the conveyor and are ready for their next task.

The Ergo Conveyor is a versatile conveyor commonly found in the automotive industry moving people working on the assembly line. The moving parts assembly of carts, lawn mowers, appliances, furnaces and ATVs also utilize ergo conveyors.

Applications

Automotive – Assembly Lines

- Modular Plastic Belt with nonskid surface or raised rib style

- Main and tension drives for surge control

- Belt width per application (width restricted by load capacity)

- Exit overrun switch

- Provided with basic sensors and valves

- Belt styles

- Exit and entrance overrun switches

- Pit mounted

- Purchase component brands

- Entrance and exit steps

- Control packages