Description

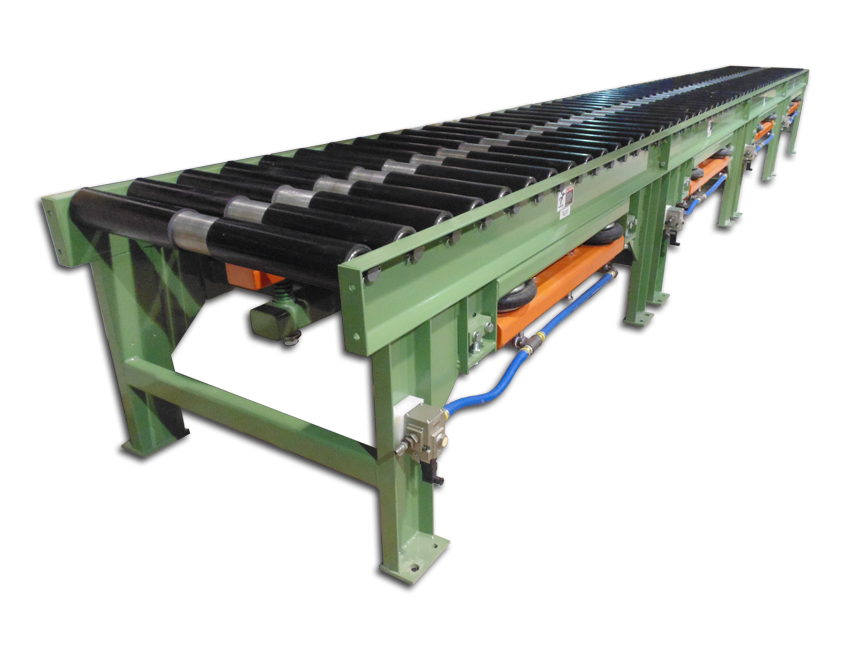

Gravity Roller Conveyors are non-powered rollers requiring an external force (gravity) to move the product. What makes these conveyors special can be roller capacity, roller shape or coating, zoning or frame function.

The function of these conveyors are to support and convey products on a bed of rollers with application specific requirement and without utilizing power. Special gravity conveyors may be handling very light products requiring special rollers or frame configurations.

Gravity Conveyors are build to order and are designed for the application. Pipe handling with trough style rollers, skid handling with zoned brakes, tamping presses supporting die changing and articulating looping conveyors are examples of where specialty gravity conveyors are used. Gravity conveyor provide a low cost solution for transportation of products.

Applications

Automotive – Power Train & Modular Assembly

- Decline zoned conveyor

- Racks – 3000 to 6000 lbs.

- Allows product to move forward as zones become available

- Rollers can be provided with a coating or sleeve that can protect the product

- Used in operator work stations and robotic work cells

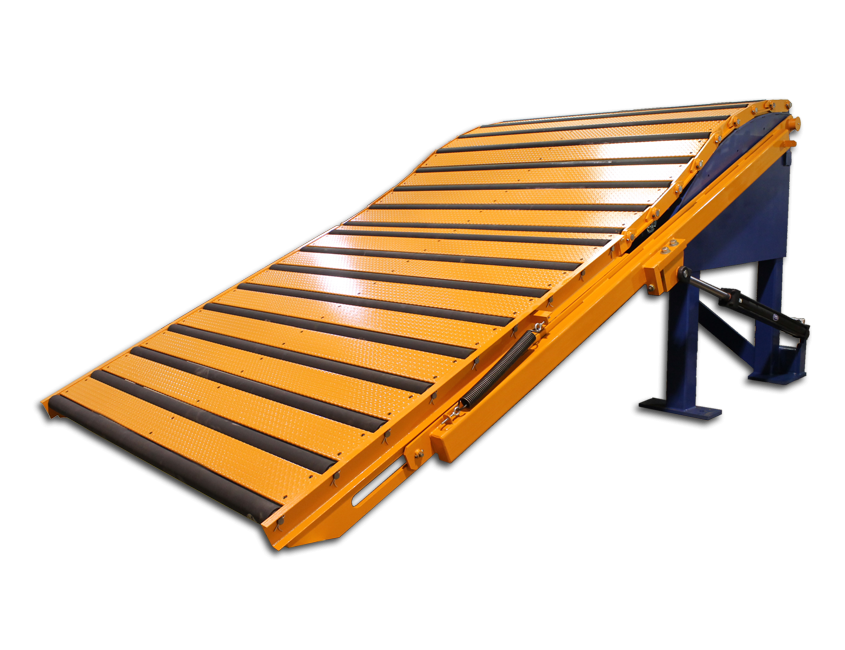

Material Processing

- Looping pit conveyors are used in the sheet metal shearing process to uncoil and feed the shear

- Conveyor raises and lowers hydraulically to allow the sheet to loop down into a pit

- Frame is segmented allowing for a smooth transition preventing the material from kinking

- Skid plates insure material remains on the conveying surface

- Rollers can be coated with a variety of materials from PVC to urethane to protect the materials from being damaged

- Roller type

- Roller costing

- Stainless steel

- Roller brakes

- Frame construction