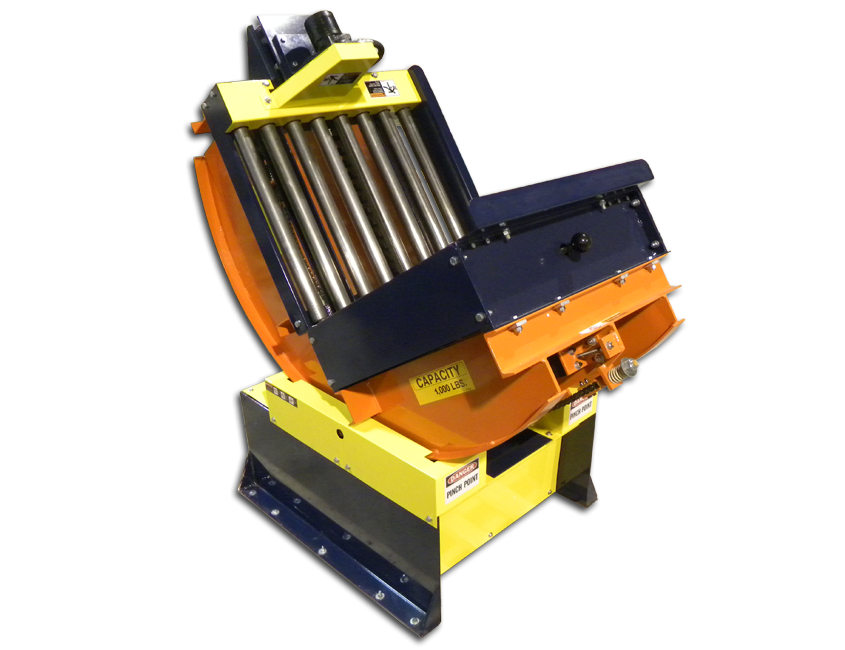

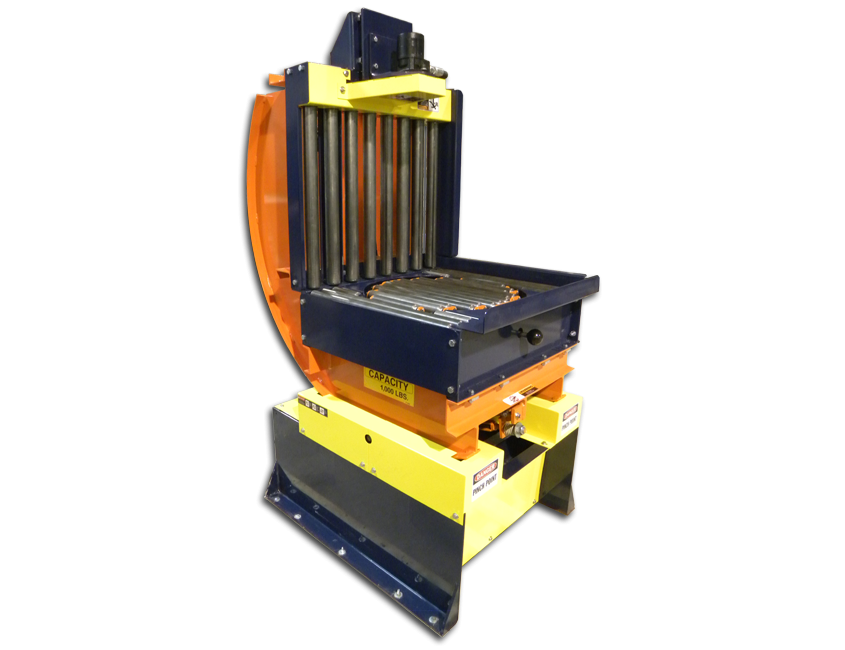

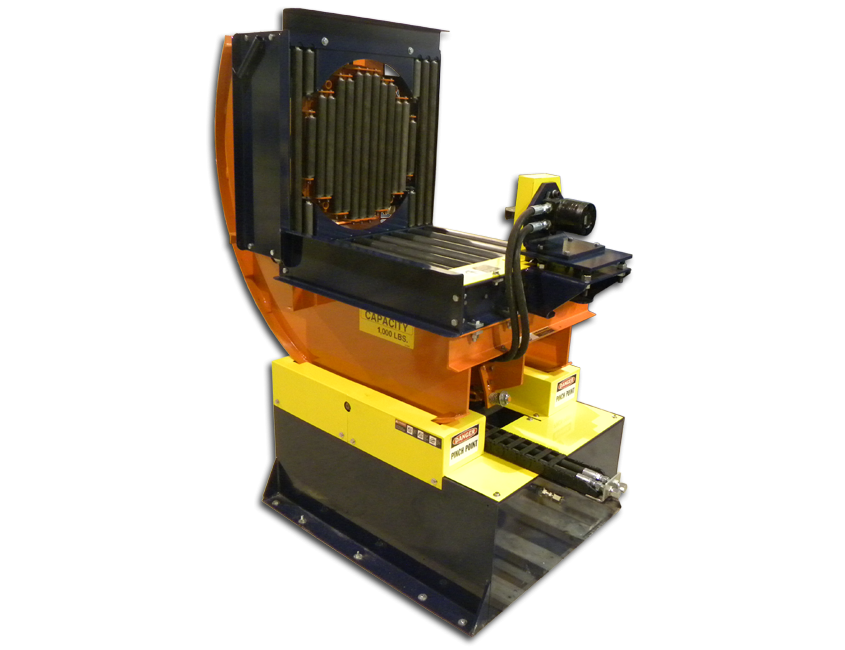

Description

This HD or Heavy Duty Upender with Turntable was designed to tilt a part 90° for inspection. A manual turntable was built into a gravity roller conveyor on one side to allow for manual movement and inspection on all sides of the part. The upender then tilted it back to the original orientation onto a powered CDLR conveyor and that could transport it in either direction.